Iron foundry basics

Practical Action

D. Ash pit

E. Refractory

F. Chimney

G. Tongs

H. Sliding cover

I. Fuel

Fig. 4.

Part of construction

Made from local clay, which would be cheaper to obtain

and be

immediately available for any repair required.

Constructed of local clay or used kerosene drums, the

bottom

sections to be lined with clay.

Can be purchased along with salamander pot, or made

by local blacksmith.

Local refractory stone

Charcoal obtained locally is recommended. Other fuels

such as coal, coke, oil, etc., can be used.

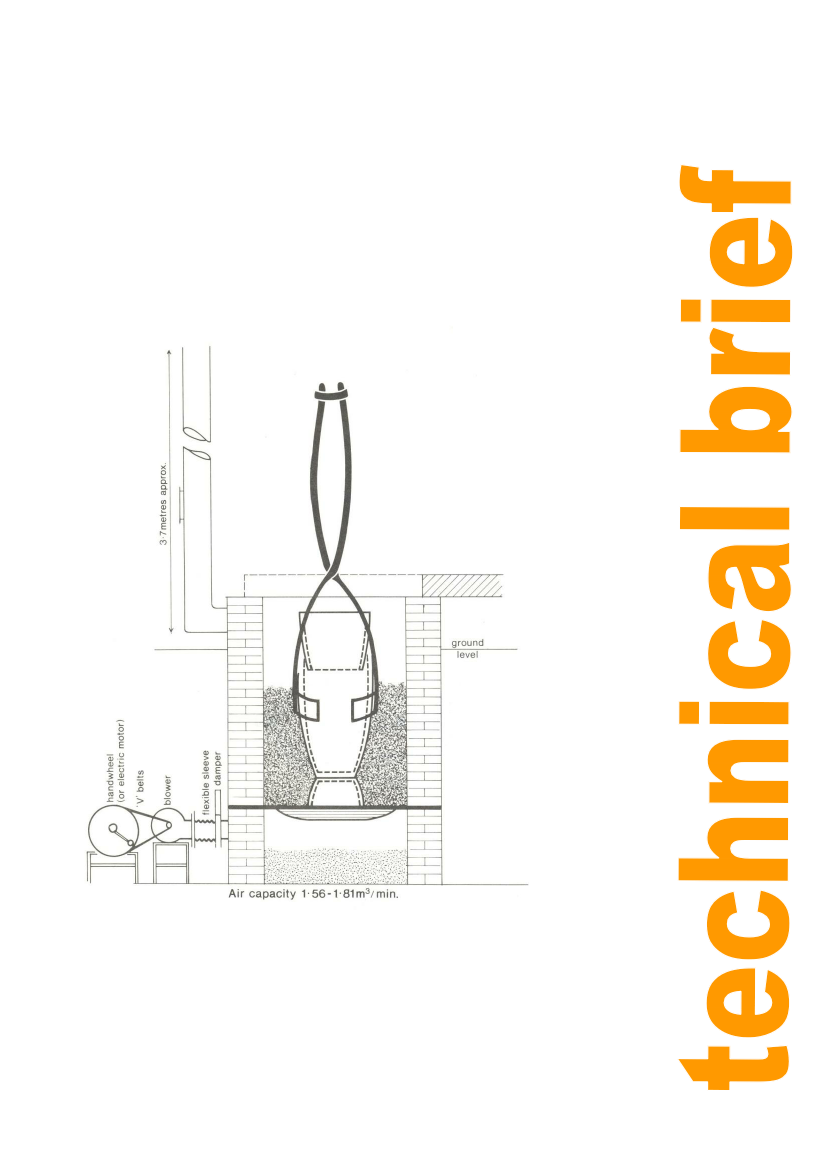

Figure 2: Crucible Furnace (Forced air)

Additional equipment required for forced-air system

Blower or Fan

Handwheel or Motor

Damper

Purchased (possibly locally) together with suitable drive belts.

Probably obtainable locally, handle to be added. To drive blower,

Instead of operating manually with handwheel. Pulleys for motor and

blower shafts required, together with suitable drive belts (V belts)

Obtained and made locally.

If an increased melting capacity is required, a cupolette can be used (Figures 5, 6 and 7).

3